|

||||||||

|

.....Services |

||||||||

|

.....Robot Technology &

Design

|

|

|||||||

|

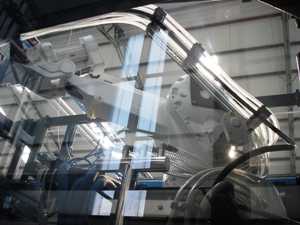

Robot Servo System Form Automation has well established Robot partnerships with both ABB and ATM Robotic Automation Systems. Robust machinery designed for factory conditions and 24/7 operation. Reliability, flexibility and ease of operation are essential. Touch Screen Technology Integrated touch screen technology allows operators to instantly change tools, tray depths and glue positioning. Servo Guillotine Highly advanced servo system allows cutting of thin to thick pad material cut to length or to register using transverse and longitudinal blades. Vacuum Pump Faster production speeds, economical and greater tool sizes. Form Automation can take care of all your production design requirements. Our

experienced staff are fully competent in all production design packages

including AutoCAD.

|

||||||||

|

|

|||||||

|

.....System and Components

|

||||||||

|

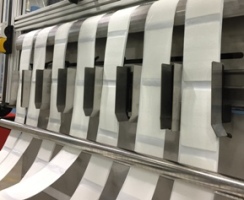

Hot Melt System Our unique hot melt system allows the operator to set precise glue size and position. Hot melt adhesive can be placed onto the underside of the pad before being positioned in the tray or direct into tray prior to pad placement. Minimum floor space All machines are designed to take up minimum floor space on your factory floor. Pad Touch screen technology allows the operator instant control of pad/bubblewrap pad size, registration and position. Autosplicing Automatic joining of bubblewrap material giving continous operation. Simple Tool Change Quick release vacuum head. Heads can be removed in seconds, either manually or pneumatically and suction cups are operator accessible. |

||||||||

|

|

|||||||

|

||||||||

|

.....Support

|

||||||||

|

We are a customer focused company who pride ourselves in supporting our customers through development, installation and production. We have full support documentation, comprehensive manuals, spares lists and support training for all machines. |

||||||||

|

play

video clip (388Kb) |

||||||||